|

Construction of an electronically

controlled automated water pumping controlling system

Undergraduate

Reserch Project 2005/2006: FSC32P2

Faculty of Science

University of Ruhuna

Matara 81000, Sri Lanka.

No part of this document may be copied/stored in any of the

printed or electronic

versions/devices without permission from the author of this

document and the inventor

of the device which is described in this document.

|

|

Author/Inventor

R.K Damith Kumara

Tele 0773664729

Siriyagama

Bundala

Weligaththa

Hambantota

|

The

system constructed here consists of following main circuit components

and parts.

-

The

sensors, which sense the water levels in the well and the tank.

-

The

voltage regulator that monitors the variation of the voltage.

-

The

main circuit to control the system.

-

The

digital display.

-

The

buzzer.

-

The

optional switch.

The

circuit is designed to operate as follows.

When the water level of the tank is lower than the sensor that is

closer to the bottom of the tank. The motor is turned ON through the

relay. This continues even after the lower sensor goes under water.

When both sensors are in contact with water, Then the motor is turned

OFF through the relay stopping the pumping.

When water is used, the water level eventually drops below the upper

sensor. However, won’t turn on the power to the motor again. In

order to turn on the motor both sensors should not contact with

water. Therefore the pumping will start only after the water level

drops below the lower sensor. This logic is illustrated in the Table

1.

|

Upper Sensor

|

Lower Sensor

|

Motor

|

|

1

|

1

|

ON

|

|

1

|

0

|

ON

|

|

0

|

0

|

OFF

|

|

1

|

0

|

OFF

|

|

1

|

1

|

ON

|

Table 1:

Conditions to turn on and off the motor depending on the signals from

the sensors in the tank.

As

can be seen above (Table 1), the motor turns on when both sensors

upper from water and turn off when both sensors contact with water.

After the motor is turned on, it keeps on the upper sensor contact

with water, respectively and for the same combination motor is

maintained at off state after the motor is turned off. In order to

perform this function the previous conditions should be stored.

During

the pumping of water the water level in the well drops. In the event

the water level is dropping below the upper censer, the motor would

not turn off even though the upper censer does not contact with

water. However, the motor will turn off automatically if both sensors

does not contact with water, which could happen only when the water

level is below the lower censer in the well. This condition

guarantees that the pumping continues only if the water level is

above the put valve. If this happens during the pumping the motor

will start again when both sensors contact with water. i.e., after

the water level is above the upper sensor in the well. This logic is

illustrated in the Table 2.

|

Upper Sensor

|

Lower Sensor

|

Motor

|

|

0

|

0

|

ON

|

|

1

|

0

|

ON

|

|

1

|

1

|

OFF

|

|

1

|

0

|

OFF

|

|

0

|

0

|

ON

|

Table 2:

Conditions to turn on and off the motor depending on the signals from

the sensors in the well.

The buzzer is to indicate the low water level of the well. if the

water level is below the lower sensor which is just above the put

valve, then motor is turned off and the buzzer is turned on and the

indicating that the motor turned off due to low water level in the

well.

The motor is OFF when the tank is filled up to the higher level and

it starts again when it goes pass the lower level of sensor. A

digital display is constructed to indicate the water level of the

tank. four different water sensors are used to determine the water

level of the tank. depending on the water level in the tank the

display will indicate one of the five regions in the tank depending

on the height. This will be displayed by a digit in the display from

0 to 4 with 4 indicating the highest level.

The voltage regulator unit monitors the fluctuations of the supply

voltage. When the supply voltage reaches a set value above which the

motor and the component of the circuit could damage, the unit

automatically cut off the main supply to the main circuit and the

motor. This will protect the motor and the other component of the

system from damages due to high voltages. when the supply voltage is

in the range between 200V to 250V AC the regulator provides a

constant 12V DC to all circuits. The relay is turned on only if the

supplied voltage is within the above range for the protection of

instruments. The range can be adjusted manually if needed. If the

supply voltage were out of the selected range the power would not

supply to the circuit. When the power is back to the safe range again

the circuit will turn on with a delay of 21/2

minutes. Similarly, the regulator will deliver power to the

circuit with the same delay after a power failure, if any, in the

house hold power supply. Hence the motor will be safe for unexpected

power fluctuations. The level of the voltage, whether the voltage is

higher, lower or at the relevant voltage level, is displayed using

state indicator LED. The red LED in higher voltages, yellow in lower

voltages and green one in relevant value and blinking green during

the delay time. That would indicate the quality of the power supply

and whether the relay is ON or OFF.

In case if one wants to fill the tank before the water level drops

below the lower sensor in the tank then one could use the push button

switch. This will turn on the motor regardless of the water level in

the tank. The motor will stop when the tank is full up to the upper

sensor. For example, if the water level is just above the lower

sensor and one wants to make sure that the tank has sufficient water

to take a bath in order to avoid the situation of not having water

during the bath due to a power failure, then the push button switch

can be used to fill the tank.

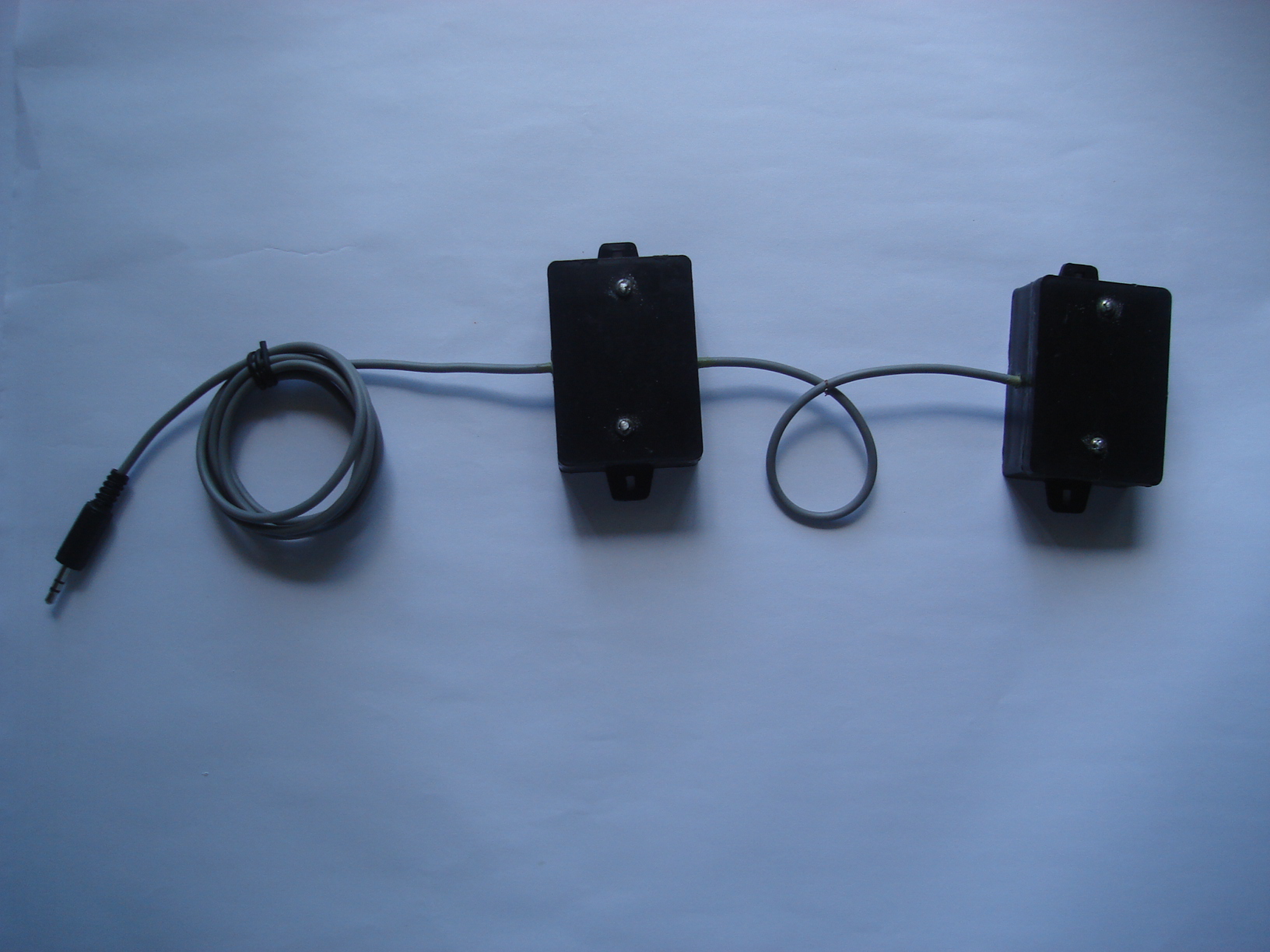

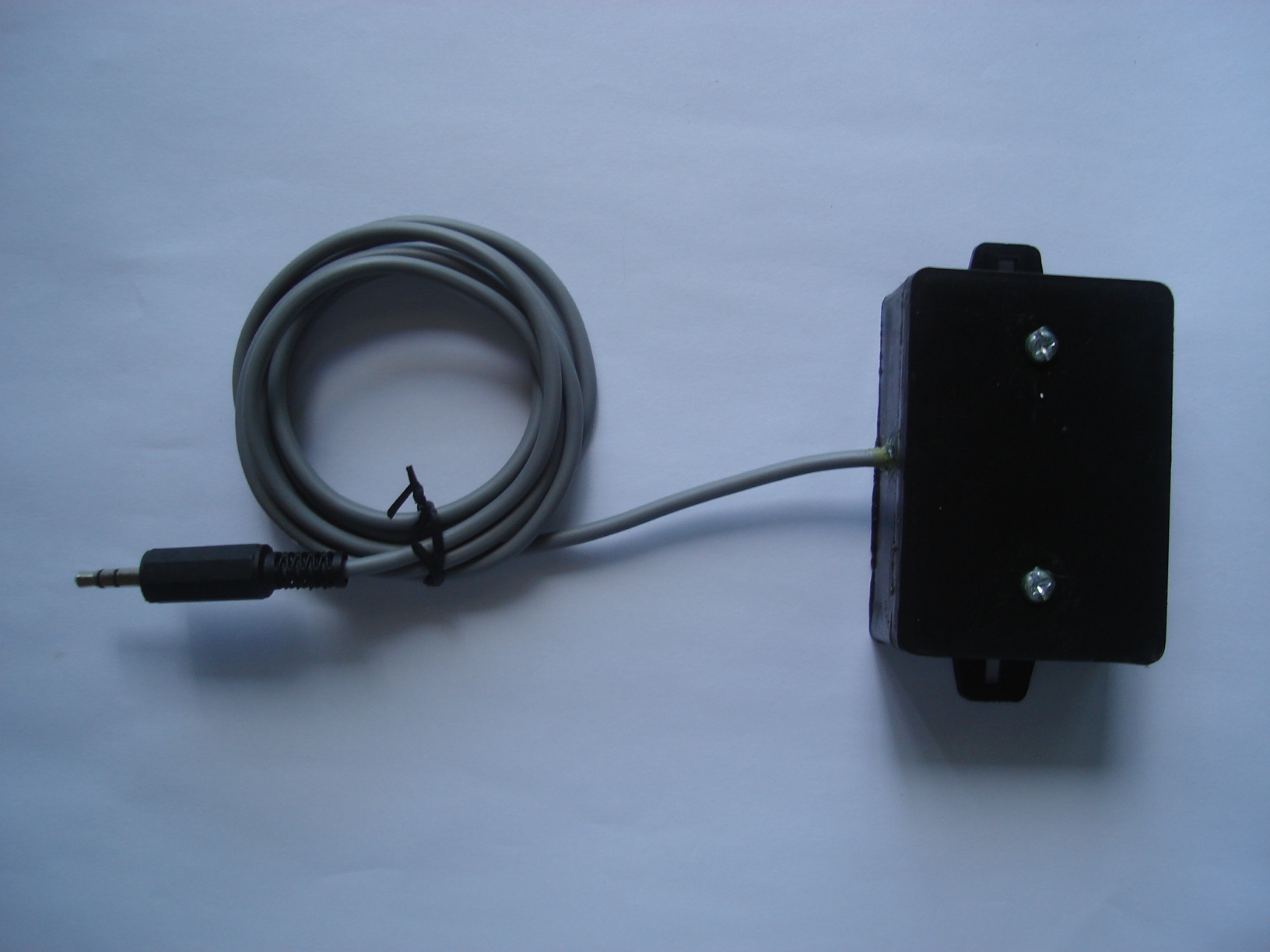

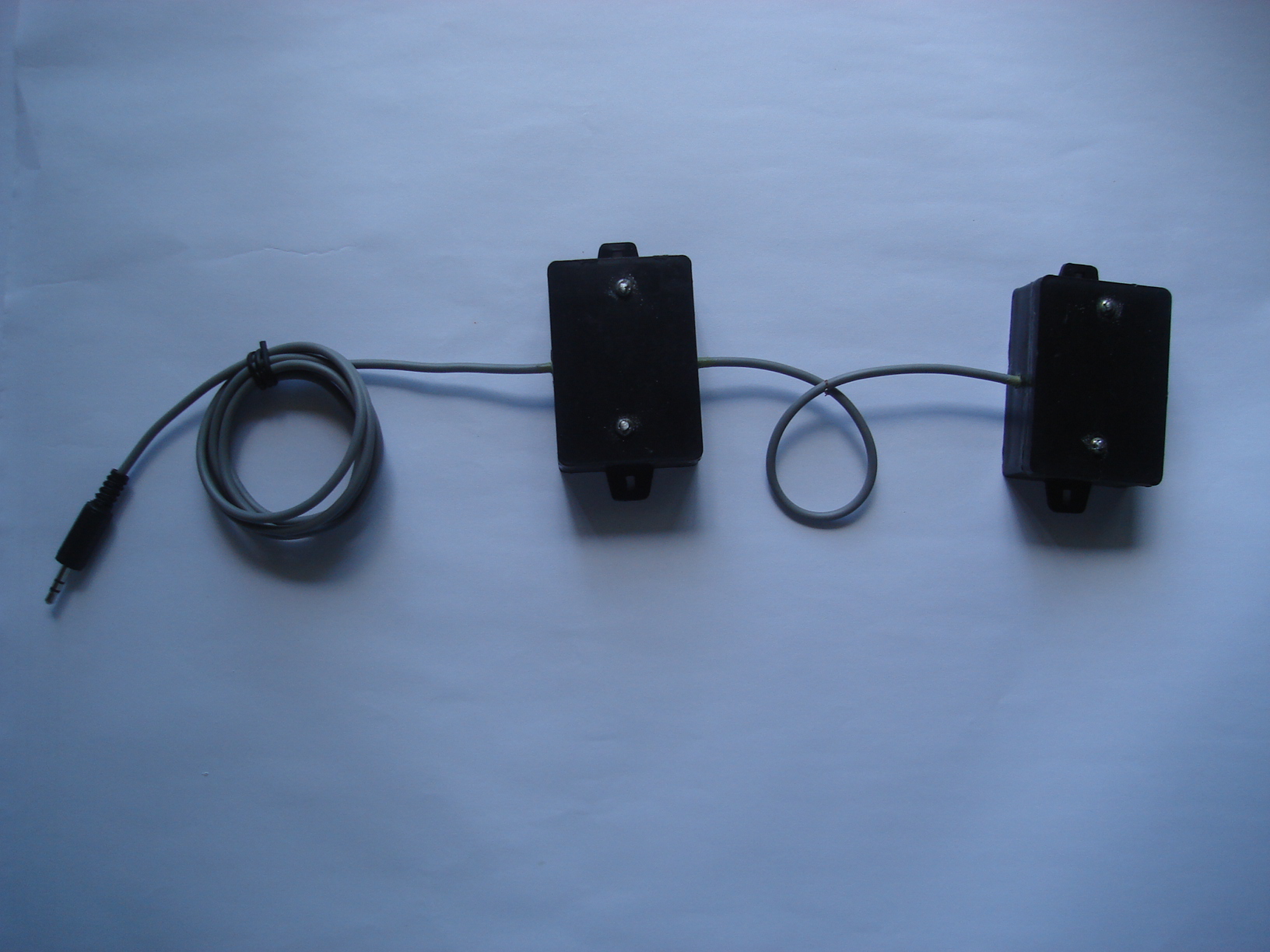

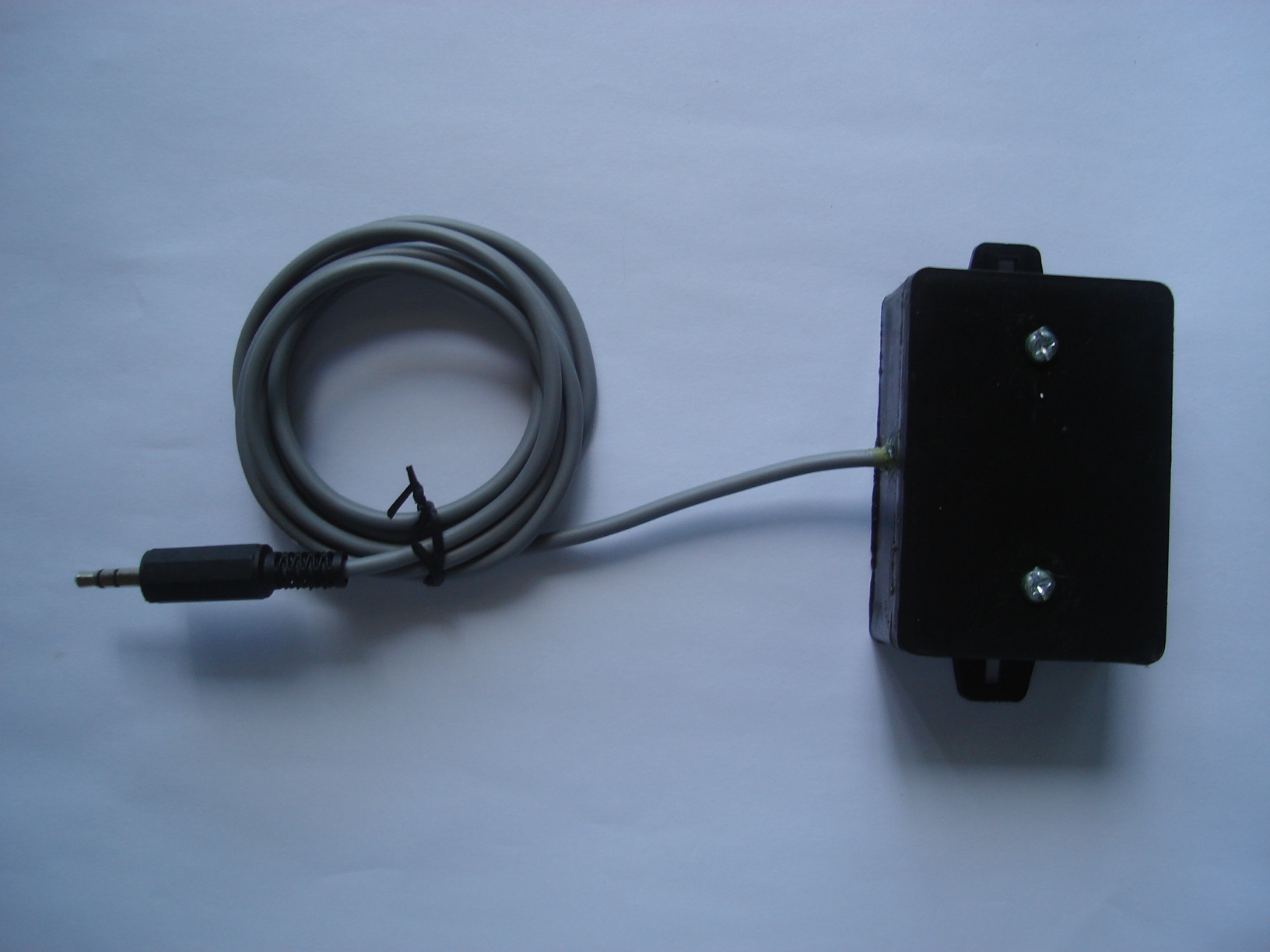

Water Sensor for well

Water Sensor for Tank

Voltage Regulator Unit

Main

Circuit

Digital

Display

Copyright by, R.K Damith Kumara, Siriyagama,

Bundala, Weligaththa, Hambantota